Measuring cleanliness and storing chemicals properly

In today's cleaning industry, ensuring cleanliness standards is essential, not just for occupant health and safety but also for preserving the standing of cleaning firms. One of the most efficient methods to achieve this is by evaluating surface cleanliness, keeping track of indoor air quality, and properly storing chemicals and cleaning agents. These measures go beyond mere aesthetics; they are essential elements in safeguarding public health, ensuring safety, and protecting the environment. The objective of this workshop was to promote cleanliness and safety by implementing consistent cleaning and maintenance routines, along with measuring and monitoring practices.

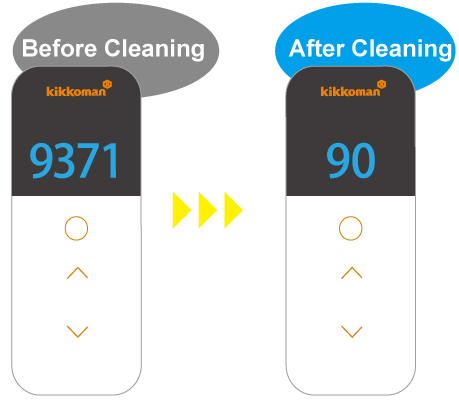

ATP Testing is recognized as an innovative approach to evaluating cleanliness. Kikkoman Biochemifa Company, known for developing the ATP Test (Kikkoman A3), took part in a "Cleaning for Health" workshop. Participants learned how to integrate ATP testing into cleaning protocols, received practical training, and discovered its advantages in enhancing hygiene levels via practical examples.

What is ATP Testing?

ATP Testing encompasses two primary types: the traditional ATP Test and the advanced ATP+ADP+AMP Test (Kikkoman A3). The former detects adenosine triphosphate (ATP), a universal molecule in living cells, offering rapid insights into overall cleanliness. However, the Kikkoman A3 goes a step further by detecting not just ATP but also its degradation compounds, ADP and AMP, collectively known as “A3”. This comprehensive approach provides heightened sensitivity, capable of identifying a broader range of microbial residues.

Benefits of Implementing Kikkoman A3

- Enhanced Cleaning Efficacy: Immediate feedback on cleaning effectiveness enables targeted cleaning efforts, ensuring thorough removal of microbial contaminants.

- Improved Hygiene Standards: Regular monitoring of ATP levels allows for the identification of cleanliness trends, facilitating targeted interventions to address recurring issues and maintain high hygiene standards.

- Quality Assurance: Sharing ATP test results with clients serves as objective evidence of cleaning efficacy, enhancing trust and credibility in cleaning services.

- Proactive Risk Management: Early detection of hygiene risks enables prompt corrective actions, mitigating the potential for contamination outbreaks and other hygiene-related incidents.

- Cost Savings: Targeted cleaning based on ATP test results optimizes resource allocation, reducing unnecessary cleaning expenses and promoting long-term cost savings.

- Environmentally friendly: The LuciPac A3 swabs utilize biomass-based polypropylene via the mass balance approach, representing a greener choice for consumers. Learn more from

To effectively implement the Kikkoman A3, cleaning companies should focus on

- Training and Education: Providing comprehensive training for cleaning staff ensures proper utilization of ATP testing devices and interpretation of test results.

- Integration into Cleaning Protocols: ATP testing should be integrated into existing cleaning protocols, with regular testing of high-touch surfaces and critical control points.

- Data Analysis and Reporting: Routine analysis of ATP test results enables the identification of cleanliness trends, facilitated by utilizing dedicated apps such as those designed for Kikkoman A3.

- Continuous Improvement: Viewing ATP testing as a tool for continuous improvement allows cleaning companies to adapt cleaning protocols based on emerging cleanliness issues.

The adoption of ATP Testing, particularly the Kikkoman A3, offers a multitude of advantages for the cleaning industry, including enhanced cleaning efficacy, improved hygiene standards, and proactive risk management. By integrating ATP Testing into their operations and embracing continuous improvement, cleaning companies can demonstrate their commitment to excellence while ensuring the health and safety of occupants.