Implementation Guide: Setting the test point

To implement the ATP Test (Kikkoman A3), below is required.

- Set the test points

- Create a rule on how to collect samples

- Setting the pass/ fail limits: ① Manufacture reference ②Reference value based on 80% tile ③Users reference

How to set test points

Hands

Please refer to the page below for further information.

Prevent infections with proper hand washing!|Test kit ❘ Kikkoman Biochemifa Company

Surfaces with direct contact of food products

|

|

|

| Cutting board | Strainer | Knife |

Even if cooked, the risk of cross-contamination increases if the utensils used afterward are contaminated.

In addition, raw foods cannot be heat sterilized, so cleaning is important.

Places that cannot be sterilized afterwards

|

|

|

| Tank filler | Packaging |

Even if heat-treated products are properly sterilized, insufficient cleaning of utensils and equipment used afterward can eventually lead to contamination.

Areas with high frequency of hand contact

|

|

|

| Oven handles | Dishwasher | Knobs |

Areas where human hands frequently come into contact are prone to get dirty. Cases of food borne illness,

norovirus often occurs through human contact with contaminated surfaces.

Areas prone to insufficient cleaning

|

|

|

|

| Blade of slicers | Belt conveyor | Fryer | Handles / Nozzles |

Others

- Areas where microbiology tests are conducted.

- Food manufacturing equipment/utensils and parts to be disassembled and cleaned.

- Locations where there is variation in measurement values

- Operation Prerequisite Program (OPRP)

- Prerequisite Program (PRP)

Implementation Guide: How to collect samples

Before collecting the samples, test points, methods and rules should be set for a unified result. Any changes in the area may affect the inspections results. Please use the LuciPac A3 correctly to gain correct results.

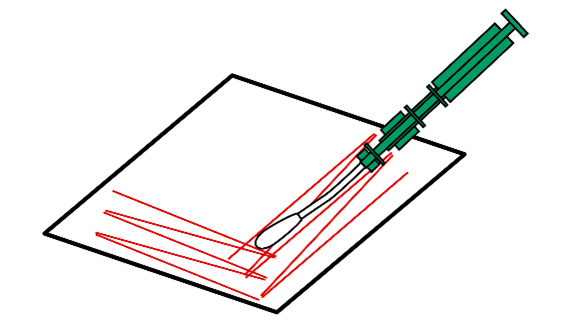

Example of a swabbing method

Swab a 10cm x 10cm sampling site both lengthwise and widthwise ten times leaving with no gaps.

ATP Test (Kikkoman A3) quick manual with Lumitester Smart

Swabbing Method

| Sample area | Swabbing method (example) |

|---|---|

| Cutting board | Swab the center of the cutting board 10 cm square area vertically and horizontally 10 times |

| Strainer, bowl | Swab the center of the strainer and bowl 10 cm |

| square area vertically and horizontally 10 times. Wipe around the inner perimeter of the upper section. | |

| Cooking area | Swab the central 10 cm square area vertically and horizontally 10 times. |

| Knife | Swab both sides of the blade completely |

| Pot | Swab the central bottom 10 cm square area vertically and horizontally 10 times. Swab around the inner perimeter of the upper section. |

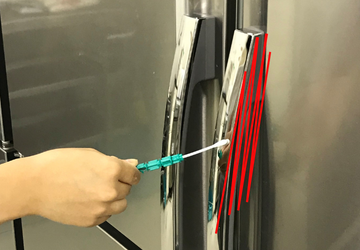

| Refrigerator (handle) | Swab the entire handle. |

| Refrigerator (inner shelf) | Swab the central 10 cm square area of the shelf vertically and horizontally 10 times. |

| Sink | Swab the corners of the sink. |

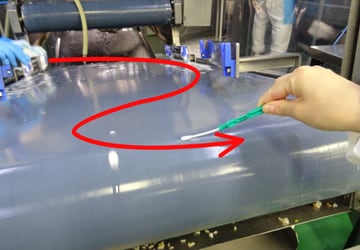

| Conveyor belt surface (resin) | Swab the belt while moving and move the swab zigzag pattern along the width of the belt. |

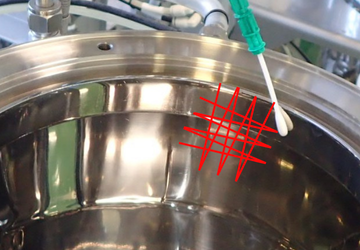

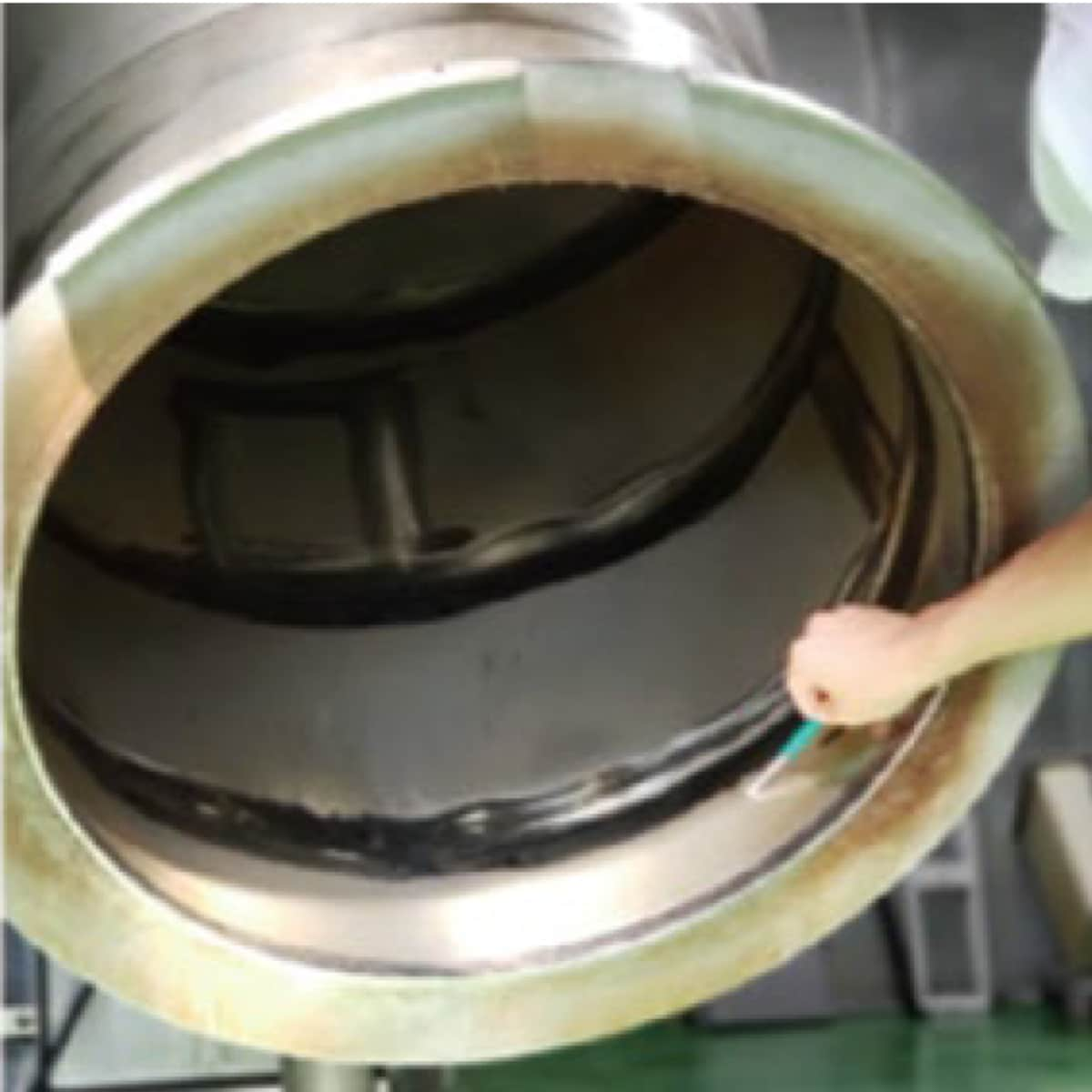

| Mixing kettle (SUS) | Swab the central bottom 10 cm square area and the inner upper edge. |

| Valve | Swab the inside of the disk, sheet, etc., evenly. |

| Slicer blade | Swab both sides of the slicer blade in a 10 cm square area vertically and horizontally 10 times. |

| Filler nozzle | Swab around the filling machine nozzle. |

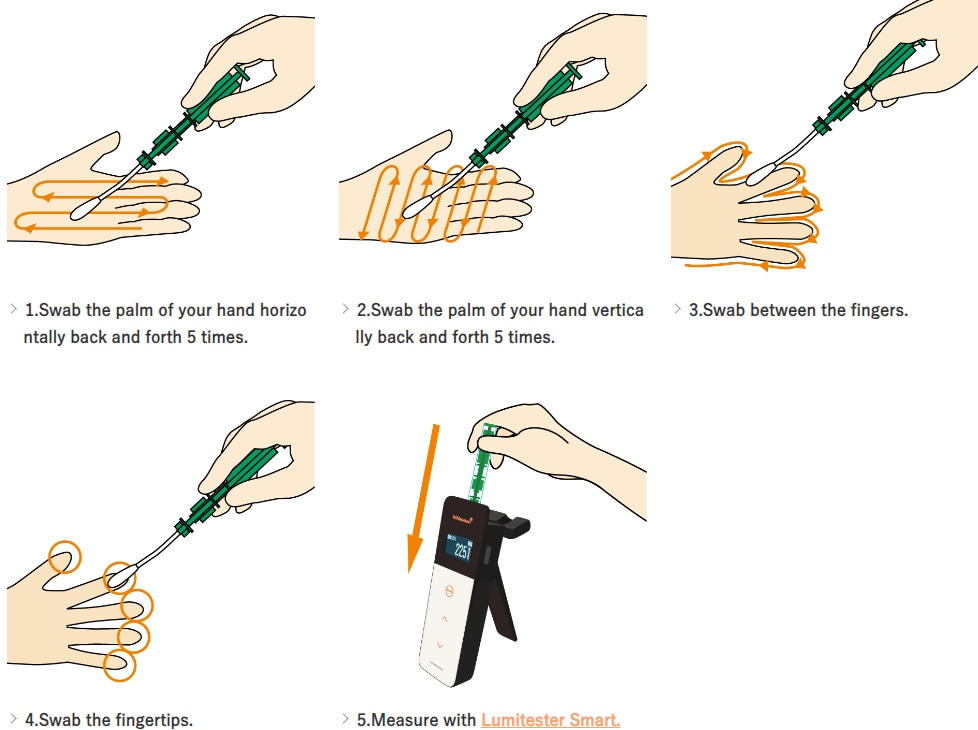

| Hands | Swab the entire palm vertically and horizontally 5 to 10 times. Swab between the fingers and fingertips. |

|

|

|

|

|

| (Knife) | (Cutting board) | (Conveyor belt) | (Slicer blade) | (Refrigerator (handle)) |

| If it is difficult to collect 10cm x 10cm for sample, the swabbing area should be 100cm2. Swab both sides evenly. Handles and edges are where soils are easy to accumulate. |

Swab the center of the cutting board 10 cm square area vertically and horizontally 10 times. | Swab the belt while moving and move the swab zigzag pattern along the width of the belt. | Swab both sides of the slicer blade in a 10 cm square area vertically and horizontally 10 times. | Swab the entire handle. |

(Hands)

Swab the entire palm vertically and horizontally 5 to 10 times. Swab between the fingers and fingertips.

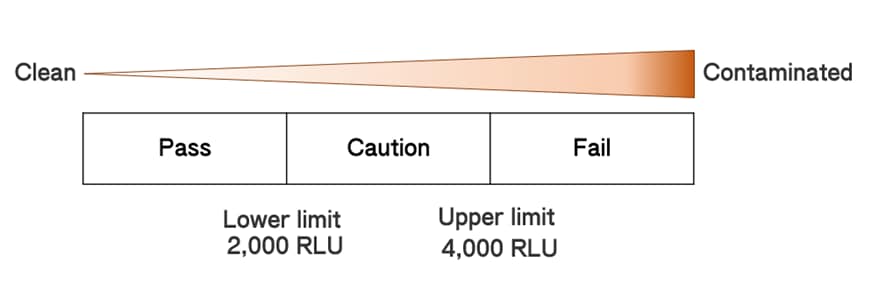

Setting the pass/fail limit: Manufacture recommendation

We recommend setting the pass/fail limit based on the manufacturer’s recommendations. Depending on the surface, material may be less likely for measured values to decrease after cleaning or washing, and the ingredients handled in various food production sites may differ.

Please refer to the link for alternative methods.

Manufacturer Recommendations

- 200 RLU or lower:

Smooth/ direct contact/ easy-to-clean surfaces (e.g., stainless, glasses) - 500 RLU or lower:

Unsmooth/ indirect contact/ hard to clean surfaces (e.g., resin products) - 2,000 RLU or lower:

Hands

Recommended pass/fail limits for hand washing: 2,000 RLU

The upper limit is set at twice of the lower limit, and 2,001~4,000 RLU will be “caution”.

*Upper limit will be twice the number of the lower limit.

*Results that are in between upper limit and lower limit should be checked thoroughly. If the results over upper limit, recleaning is required.

Recommended reference values by field of implementation

Food production site

| Testing Purpose | Test point | Lower limit | Upper limit | |

|---|---|---|---|---|

| Pass (≦) | Caution | Fail (>) | ||

| Hygiene education pre-work hygiene checks | hand | 2,000 | 2,001~4,000 | 4,000 |

| Hygiene management of manufacturing lines and cooking utensils, etc. | Conveyor belts (resin) | 500 | 501~1,000 | 1,000 |

| Blending kilns (stainless steel) | 200 | 201~400 | 400 | |

| Slicers | 200 | 201~400 | 400 | |

| Tank filler | 200 | 201~400 | 400 | |

| Valves | 200 | 201~400 | 400 | |

| Control buttons | 500 | 501~1,000 | 1,000 | |

| Cutting boards | 500 | 501~1,000 | 1,000 | |

| Knives | 200 | 201~400 | 400 | |

| Cooking tables | 200 | 201~400 | 400 | |

| Strainers/bowls/tray | 200 | 201~400 | 400 | |

| Pot | 200 | 201~400 | 400 | |

| Refrigerator (handles) | 200 | 201~400 | 400 | |

| Refrigerator (internal shelves) | 500 | 501~1,000 | 1,000 | |

| Sink | 200 | 201~400 | 400 |

Catering/Food Services/ Cafeteria

| Testing Purpose | Test point | Lower limit | Upper limit | |

|---|---|---|---|---|

| Pass (≦) | Caution | Fail (>) | ||

| Hygiene education pre-work hygiene checks | hand | 2,000 | 2,001~4,000 | 4,000 |

| Hygiene management of manufacturing lines and cooking utensils, etc. | Cutting boards | 500 | 501~1,000 | 1,000 |

| Knives | 200 | 201~400 | 400 | |

| Cooking tables | 200 | 201~400 | 400 | |

| Strainers/bowls/tray | 200 | 201~400 | 400 | |

| Pot | 200 | 201~400 | 400 | |

| Refrigerator (handles) | 200 | 201~400 | 400 | |

| Refrigerator (internal shelves) | 500 | 501~1,000 | 1,000 | |

| Sink | 200 | 201~400 | 400 | |

| Dishes | 200 | 201~400 | 400 | |

| Lunch boxes/containers | 200 | 201~400 | 400 |

Janitorial/Cleaning/K-12

The ISSA Clean Standards provides a structured approach for schools and institutional facilities to evaluate the efficiency of their cleaning methods using ATP meters alongside traditional audits.

The ISSA Clean Standards |Test kit ❘ Kikkoman Biochemifa Company

| Testing Purpose | Test point | Lower limit | Upper limit | |

|---|---|---|---|---|

| Pass (≦) | Caution | Fail (>) | ||

| Hygiene education pre-work hygiene checks | hand | 2,000 | 2,001~4,000 | 4,000 |

| Environmental monitoring of surface hygiene | Desks and similar surfaces such as worktables | 2,000 | 2,001~4,000 | 4,00 |

| Cafeteria or breakroom tables | 2,000 | 2,001~4,000 | 4,000 | |

| Restroom stalls and stall doors | 2,000 | 2,001~4,000 | 4,000 | |

| Sink fixtures and sink surroundings | 2,000 | 2,001~4,000 | 4,000 | |

| Floors | 2,000 | 2,001~4,000 | 4,000 | |

| Drinking fountains | 2,000 | 2,001~4,000 | 4,000 | |

| Doorknobs | 2,000 | 2,001~4,000 | 4,000 | |

| Handles | 2,000 | 2,001~4,000 | 4,000 | |

| Doors | 2,000 | 2,001~4,000 | 4,000 | |

| Countertops | 2,000 | 2,001~4,000 | 4,000 | |

| Handrails | 2,000 | 2,001~4,000 | 4,000 | |

| Light switches | 2,000 | 2,001~4,000 | 4,000 | |

| Faucets | 2,000 | 2,001~4,000 | 4,000 |

Approach to Inspection Frequency

| Frequency | Examples of test points |

| Daily |

|

| Weekly |

|

| Monthly |

|

| Irregular |

|

Incorporate the above approach into food hygiene standards, establish inspection frequencies, and manage and operate accordingly.

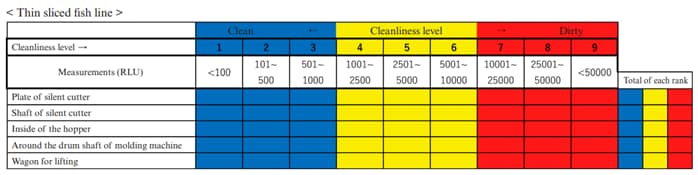

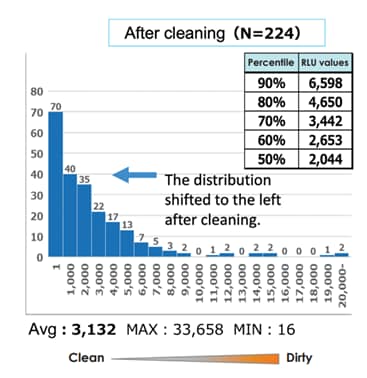

Setting the pass/fail limit: 80% passing rate

If more practical standards are desirable, or if measurement data are accumulated, you can set the pass/fail limit that meet the current condition of your facility. Below is an example data taken at the University of Wisconsin-Madison facility.

1.Set Test Points

Select multiple test points and perform an ATP Test (Kikkoman A3) for swabbing sample or rinse water.

A total of 10 test points, 5 test points from each CIP and COP were selected.

Test point of CIP

Test point of COP

2.Collect data

Collect from before cleaning and after cleaning. Each test point should be tested 5 times to check the range.

| # of test conducted (RLU) | |||||

| Test point | 1st | 2nd | 3rd | 4th | 5th |

| 1 | 39 | 22 | 14 | 30 | 20 |

| 2 | 68 | 498 | 35 | 12 | 10 |

| 3 | 9 | 131 | 182 | 14 | 119 |

| 4 | 14 | 13 | 43 | 34 | 39 |

| 5 | 24 | 19 | 23 | 6 | 25 |

| 6 | 18 | 12 | 2 | 3 | 62 |

| 7 | 11 | 7 | 10 | 17 | 19 |

| 8 | 9 | 61 | 20 | 3 | 8 |

| 9 | 12 | 9 | 24 | 8 | 22 |

| 10 | 13 | 11 | 21 | 5 | 12 |

Test point 1~5 is CIP after cleaning and test point 6~10 is inside the piping after COP disassembly and cleaning

3.Setting the pass limit

For each inspection point, the second-highest value from the collected data was extracted (indicated in orange). This value is used as the pass limit, ensuring that approximately 80% of the results pass.

| # of test conducted (RLU) | |||||

| Test point | 1st | 2nd | 3rd | 4th | 5th |

| 1 | 39 | 22 | 14 | 30 | 20 |

| 2 | 68 | 498 | 35 | 12 | 10 |

| 3 | 9 | 131 | 182 | 14 | 119 |

| 4 | 14 | 13 | 43 | 34 | 39 |

| 5 | 24 | 19 | 23 | 6 | 25 |

| 7 | 11 | 7 | 10 | 17 | 19 |

| 6 | 18 | 12 | 2 | 3 | 62 |

| 8 | 9 | 61 | 20 | 3 | 8 |

| 9 | 12 | 9 | 24 | 8 | 22 |

| 10 | 13 | 11 | 21 | 5 | 12 |

If the extracted value is not a whole number, it is rounded up for practical use. The following figure provides examples of pass limit for each inspection point.

| Test Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Pass limit (RLU) | 30 | 70 | 135 | 40 | 25 | 20 | 20 | 20 | 25 | 15 |

4.Confirm the validity of pass limits

To verify whether the set pass limit is appropriate, samples should be collected both before and after thorough cleaning. Once the post-cleaning data is gathered, evaluate the results, if they meet the criteria, the pass limit is considered valid. However, if the pass rate is too high, consider whether further improvements can be made and adjust the pass limit to align with the 80% threshold. Additionally, setting excessively strict limits may discourage employees, so ensure the standards are both effective and motivating.

5.Revalidation

The pass limit must be revalidated whenever there are changes to the cleaning detergent, modifications in the manufacturing process, or a switch to a different supplier. These factors can impact cleanliness levels and overall effectiveness, making it essential to reassess and confirm that the established pass limit remains appropriate and reliable under the new conditions.

Establishing Limits Based on Users Cases

Case Study 1: Food and Beverage industry

They switched from a conventional ATP test to Kikkoman A3 to enhance hygiene management in their factories and cafeteria. Their pass/fail limits were set based on initial benchmarks (1,000 RLU for factories, 3,000 RLU for cafeterias) and Kikkoman Biochemifa’ s published research on ATP testing for allergen control. Stricter limits were applied to high-risk surfaces like knives and cutting boards. These thresholds are continuously monitored and adjusted based on operational data.

| November 4,2019 (Mon) | November 11, 2019 (Mon) | November 18, 2019 (Mon) | November 25, 2019 (Mon) | December 9, 2019 (Mon) | December 16, 2019 (Mon) | December 23, 2019 (Mon) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A3 Test | TPC | A3 Test | TPC | A3 Test | TPC | A3 Test | TPC | A3 Test | TPC | A3 Test | TPC | A3 Test | TPC | ||||

| Inspection Areas | Limit <1,000 RLU | Limit <100 | Limit <1,000 RLU | Limit <100 | Limit <1,000 RLU | Re-examine | Limit <100 | Limit <1,000 RLU | Limit <100 | Limit <1,000 RLU | Re-examine | Limit <100 | Limit <1,000 RLU | Limit <100 | Limit <1,000 RLU | Re-examine | Limit <100 |

| C 01: Service tank vales | 11 | 0 | 5 | 0 | 10 | - | 0 | 11 | 0 | 1,335 | 6 | 0 | 4 | 0 | 8 | - | 0 |

| C 03: High pressure pump outlets | 10 | 0 | 8 | 0 | 4 | - | 0 | 5 | 0 | 7 | - | 0 | 5 | 0 | 5 | - | 0 |

| C 04: Strainer housings | 8 | 0 | 2 | 0 | 18 | - | 0 | 4 | 0 | 5 | - | 0 | 87 | 0 | 4 | - | 0 |

| C 05: Powder conveying lines | 13 | 0 | 8 | 0 | 139 | - | 0 | 14 | 0 | 30 | - | 0 | 16 | 0 | 13 | - | 0 |

| C 06: Transfer fans | 805 | 0 | 11 | 0 | 222 | - | 0 | 3 | 0 | 8 | - | 0 | 4 | 0 | 64 | - | 0 |

| C 07: Dehumidification lines | 7 | 23 | 77 | 0 | 14 | - | 0 | 8 | 0 | 11 | - | 0 | 2 | 0 | 16 | - | 0 |

-

Service tank valves

-

High-pressure pump outlets

-

Strainer housings

-

Powder conveying lines

-

Transfer fans

-

Dehumidification lines

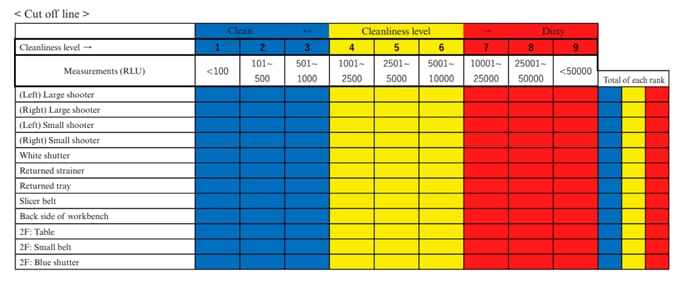

Case Study 2: Seafood processing plant

Pass and fail limits using a three-tier system: Pass (Blue) for acceptable cleanliness, Fail (Red) for contamination requiring immediate re-cleaning, and Caution (Yellow) for borderline results needing monitoring. Their limits were based on Kikkoman Biochemifa’s reference values, industry research, and benchmarks from other factories. When precise limits were unclear, they initially set a provisional threshold where about 80% of tests passed and refined the values over time. Monthly reviews of test data allowed continuous adjustments to maintain strict hygiene standards. This adaptive approach ensured real-time contamination detection, faster corrective actions, and improved overall hygiene management.

Case Study 3: Hotel

Pass and fail limits using an 80th percentile approach, with 5,000 RLU as the pass limit, 10,000 RLU as the failure limit, and values in requiring monitoring. These limits were established through baseline testing of 50-100 locations, analyzing pre- and post-cleaning ATP results, and setting provisional benchmarks where 80% of test points showed acceptable cleanliness. They continuously review and refine these limits, aiming to lower the pass threshold to 2,000 RLU in line with Kikkoman Biochemifa’s hygiene standards.

Case Study 4: Welfare facility kitchen

ATP testing begins with measuring tap water as a baseline, followed by testing hands, cutting boards, knife handles, the back of refrigerator handles, and mixer blades. The manual provides detailed instructions on swabbing techniques, including applying enough pressure to slightly bend the swab. Pass and fail limits follow Kikkoman Biochemifa’s recommended values without modification.

| Test point | Method & Conditions | Limits | Action if Above Standard Value |

|---|---|---|---|

| ① Tap Water | Run tap water through frequently used faucet openings. | 0–30 RLU | Clean faucet, flush water, and retest. |

| ② Hands | Dry hands after washing with alcohol spray. ① Swab palm and back of the hand vertically 5 times each. ② Swab between thumb and little finger to wrist. ③ Swab around nails 3 times. | ≤1500 RLU | Rewash, retest, check handwashing method and hand condition. |

| ③ Cutting Board | Swab a 10 cm² disinfected area (post-preparation) vertically 5 times. | ≤500 RLU | Rewash, retest, check for surface damage. |

| ④ Knife Handle | Swab a disinfected knife handle (post-preparation): ① Swab 3 sides of handle ② Swab entire handle-to-blade area. | ≤1000 RLU | Rewash, retest, check cleaning method. |

| ⑤ Refrigerator Handle | Swab frequently touched refrigerator handle: ① Swab entire handle 5 times vertically ② Swab attachment area. | ≤2000 RLU | Rewash, retest, check cleaning method. |

| ⑥ Mixer Blade | Swab a disinfected mixer blade (post-preparation): ① Swab blade 5 times ② Swab blade surface 5 times ③ Swab attachment area. | ≤500 RLU | Rewash, retest, check cleaning method. |

| Bowl (if no mixer available) | Swab a 20–30 cm washed bowl: ① Swab a 10 cm² section 5 times vertically ② Swab inside the rim. | ≤200 RLU | Rewash, retest, check cleaning and storage method. |

Note: Apply enough pressure so the swab slightly bends (~10 cm² area).

| Surface type | Limits |

| Smooth, easy-to-clean surfaces | ≤200 RLU |

| Uneven, difficult-to-clean surfaces | 500–1000 RLU |

Note: Apply enough pressure so the swab slightly bends (~10 cm² area).

Case Study 5: Beer factory

The beer factory set stricter ATP cleanliness standards compared to manufacturer recommendations. While the ATP device manufacturer suggests 300 RLU for food equipment, the factory aimed for a much lower threshold, initially targeting 100 RLU and later maintaining 30 RLU for most areas. By setting specific numerical goals, they significantly improved individual hygiene awareness among employees.

Case Study 6: Meat and Poultry

To establish an effective allergen control measure using ATP Testing, conducted a validation study comparing ATP levels and protein content across chicken, pork, and beef. ATP results were shown to correlate closely with protein levels measured by the Bradford method. Found that ATP values under 500 RLU consistently corresponded to less than 1 ppm of residual meat protein—meeting Japan’s allergen labeling exemption threshold. Based on this correlation, a pass/fail limit of <500 RLU was set to help verify cleaning effectiveness and minimize allergen cross-contamination risk in daily hygiene monitoring.

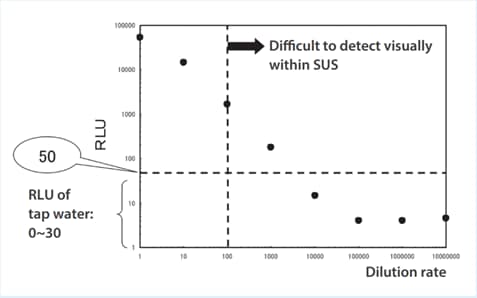

Case Study 7: Soymilk Plant

It is said that tap water typically shows a reading of 0 to 30 RLU. When soymilk is diluted 10,000 times, it exhibits a similar RLU level. Therefore, our factory has established a management threshold of 50 RLU, aiming to achieve this level of cleanliness through washing.

Similarly, we investigated the correlation between the concentration of a soymilk-based beverage (malt coffee flavor) and its RLU values and found comparable results. Based on this data, we have set the ATP Test management threshold to 50 RLU for all types of soymilk beverages produced at the facility.

Case Study 8: Meat Manufacturing Plant

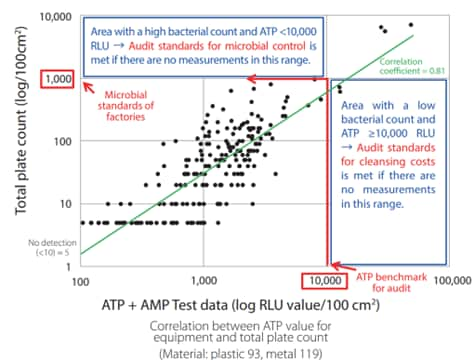

If the pass/fail limit is set at 10,000 RLU, and there are any cases where the ATP test result is below 10,000 RLU but the microbial test exceeds the internal standard (1,000 CFU/100 cm²)—in other words, if any data points appear in the upper-left boxed area of figure—this would indicate that the sample “passes the ATP test but fails the microbial test.” This would mean that 10,000 RLU is not an appropriate pass/fail limit.

However, based on the data in the figure, there were no samples that showed ATP test results below 10,000 RLU while exceeding 1,000 CFU/100 cm² in the microbial test.

On the other hand, if there are samples where the ATP test result exceeds 10,000 RLU but the microbial test result is below 1,000 CFU/100 cm²—i.e., data points in the lower-right boxed area this would indicate that the sample “passes the microbial test but is being subjected to unnecessarily strict cleaning requirements,” implying over-cleaning or excessive cleaning costs.

Looking at the data in figure, only a few samples fell into this area, and thus we determined that the 10,000 RLU pass/fail limit is acceptable.