For use in JAS standards, HACCP and GAP programs in food processing!

(For environmental hygiene and employee hygiene education)

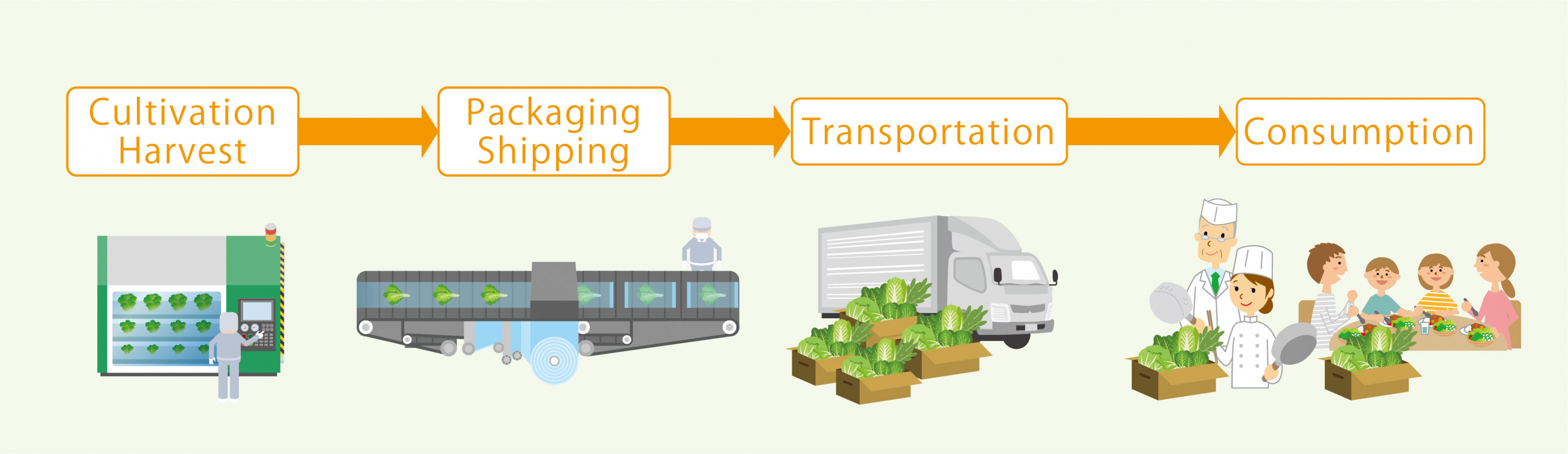

ATP bioluminescence-based test methods have been included in Japanese National Standards (JAS) for hygiene safety in the processing of leafy greens. This is important recognition of the effectiveness of the use of ATP in essential food hygiene applications. Through the use of ATP Tests (A3 technology) using the Kikkoman Lumitester Smart and LuciPac A3 Surface, hygiene monitoring is made possible during all phases of processincluding cultivation, harvest, packaging, shipping, and transportation.

*JAS=Japanese Agricultural Standards

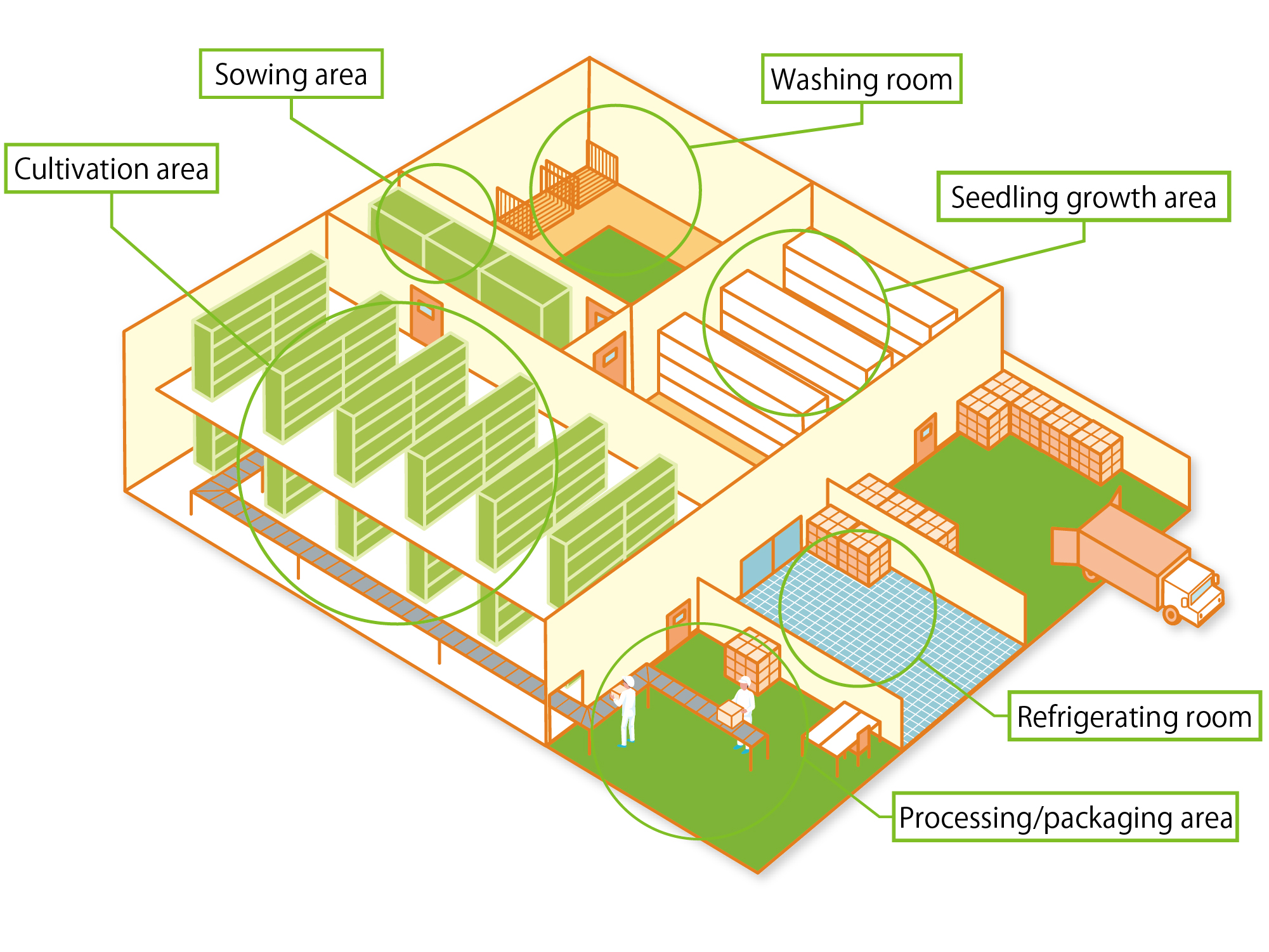

ATP Test (A3 technology) is used in a range of places.

Through ATP Test (A3 technology) using Lumitester Smart and LuciPac A3 Surface, hygiene monitoring is possible during cultivation, harvest, packaging, shipping, and transportation in plant factories.

What is ATP Test (A3 technology)?

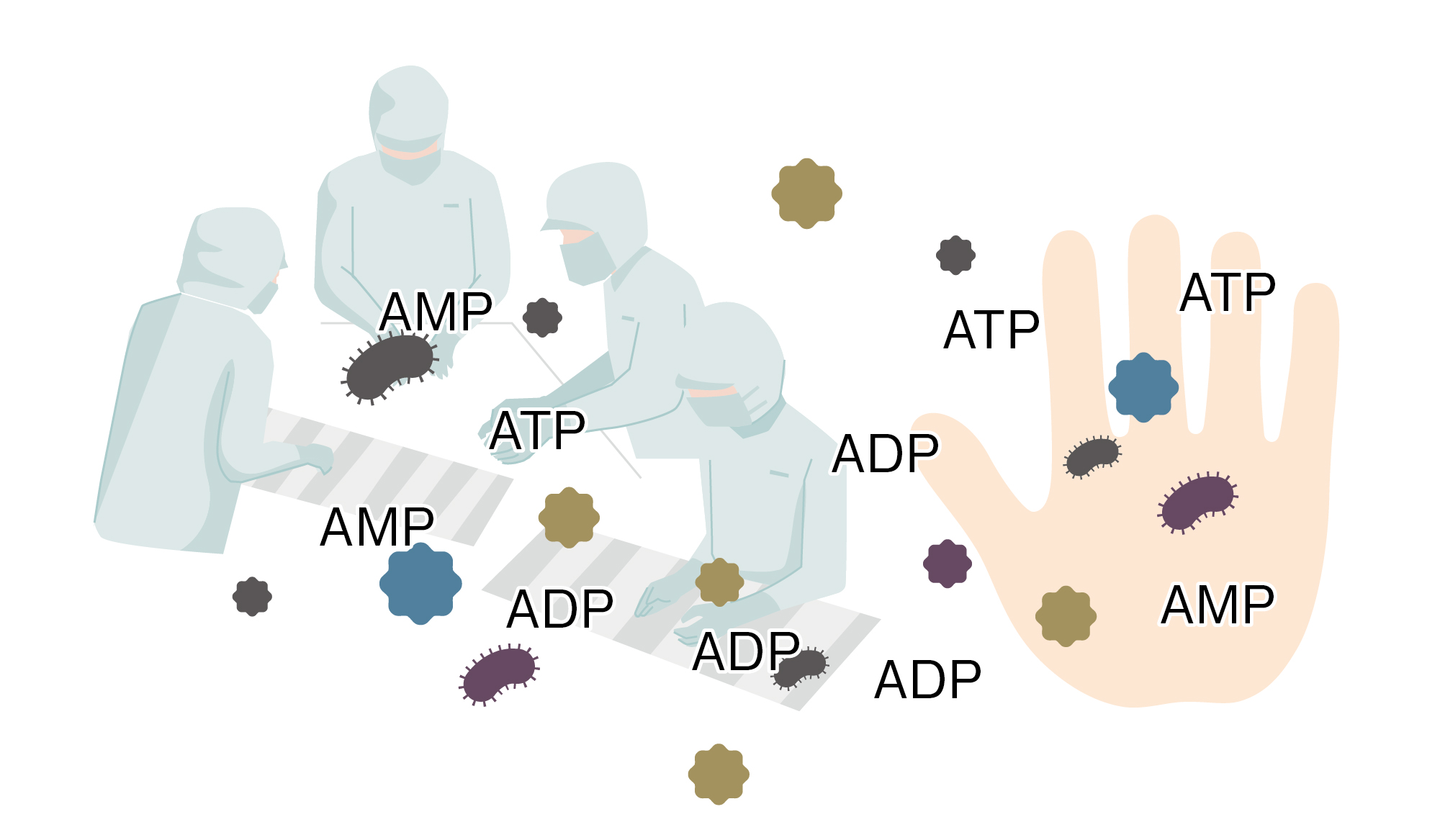

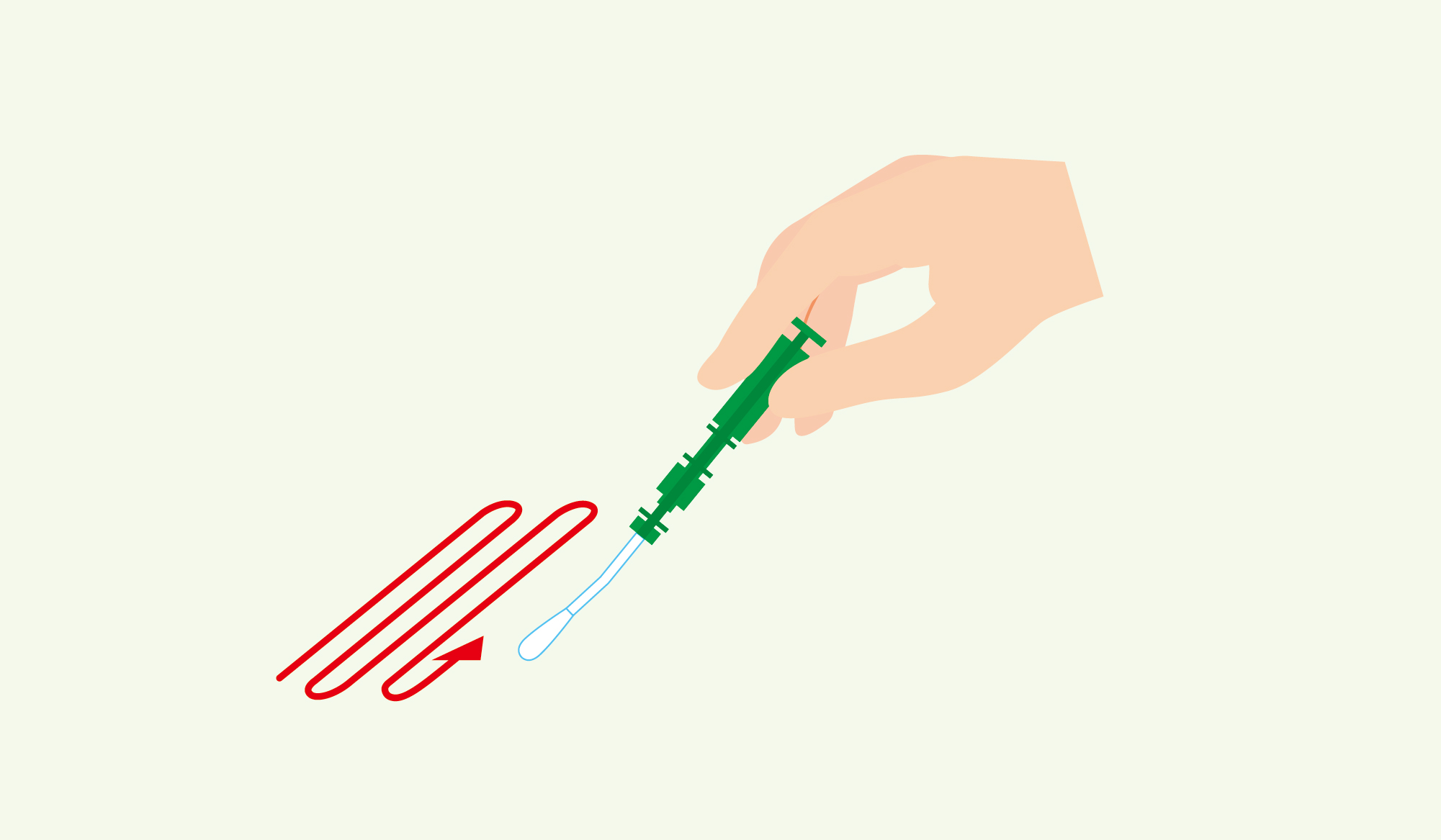

Foodborne bacteria and other contaminants that cannot be seen can be present throughout in food processing plants. The ATP Test (A3 technology) is a sensitive inspection method that can measure surface hygiene using ATP as an indicator of contamination. Once uncovered, these risks associated with residual contamination can be reduced by re-cleaning the work site. Being able to uncover the effectiveness of cleaning can also be used as a hygiene training tool worker, to make them more aware of proper surface cleaning or hand washing.

-

Before cleaning

The high level of A3 (ATP + ADP + AMP) is indicative of insufficient hand washing and is associated with the potential for high levels of soil and microbes on the person’s hands.

-

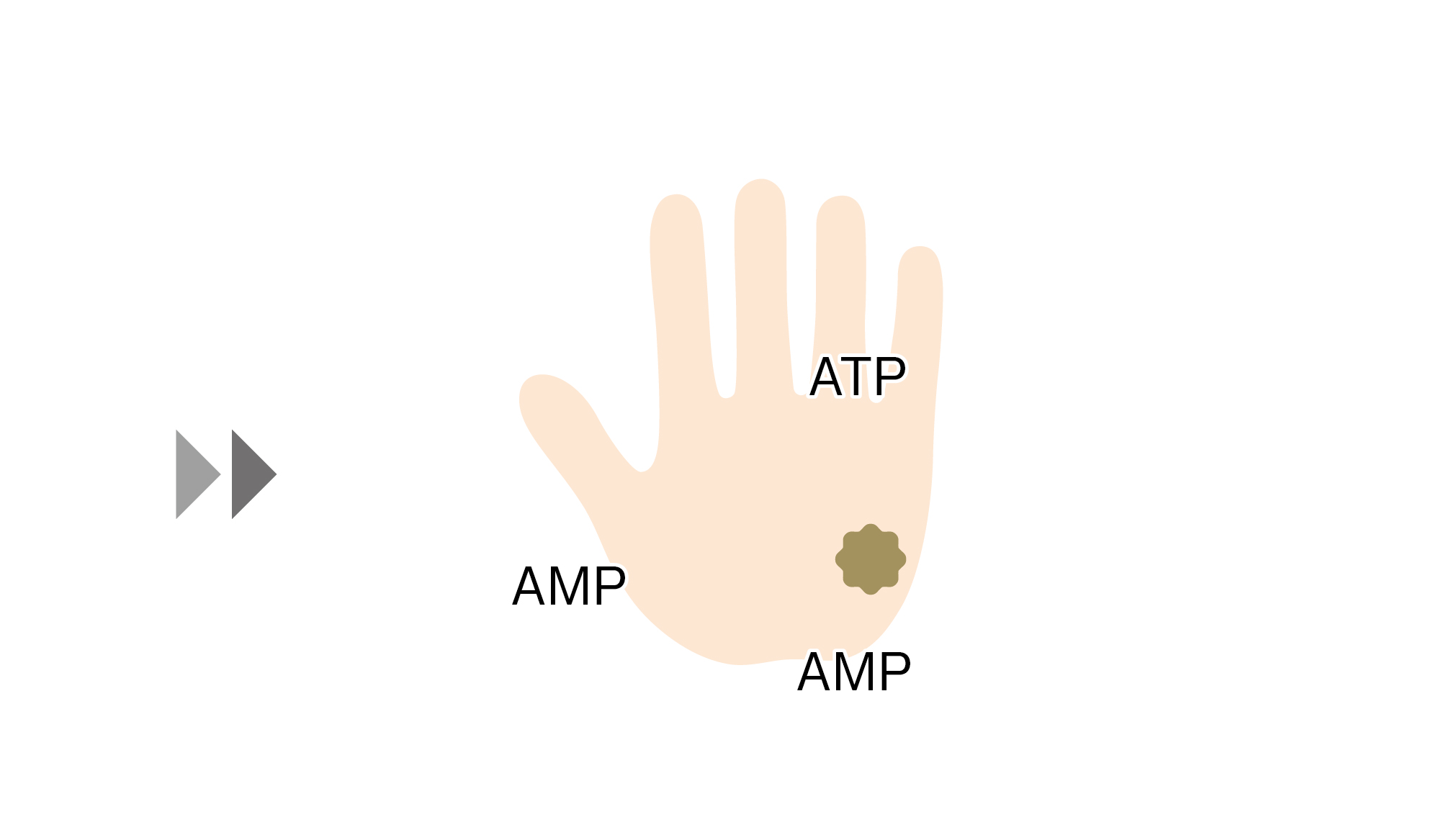

After cleaning

After hand washing, the measured reduction of A3 (ATP + ADP + AMP) is indicative of the reduction of soil and microbes on the hands due the hand washing having been done properly.

-

ATP Test (A3 technology) is an easy way to check cleanliness!

Examples of use

ATP Tests (A3 technology) have been used in food production sites for decades. Using an ATP Test (A3 technology), which only takes 10 seconds for the measurement, can be used to improve the hygiene awareness of workers and the hygiene management of machinery, facilities, containers, etc., in accordance with HACCP and many national and international standards .

Examples of benchmark values by inspection location

| Inspection locations (examples) | Reference benchmark value (RLU) |

|---|---|

| Hand | ≦2000 |

| Harvesting trays, cutting boards, conveyor belts, refrigerator shelves, water tanks, cultivation panels, etc. (made of resin) | ≦200 |

| Scissors, kitchen knives, working tables, refrigerator handles, sinks, etc. (made of SUS) | ≦500 |

*If measurement results exceed the benchmark value, it may be due to insufficient cleaning.

*The benchmark value varies depending on site conditions and other factors and needs to be reviewed periodically.

*Machinery and equipment that come in direct contact with leafy greens are particularly important inspection points.

*According to the HACCP concept, hygienic hand washing is also important when wearing gloves.