The Importance of Utility Management in General Hygiene Programs

In March 2024, a serious issue emerged when individuals consuming red yeast rice supplements developed kidney-related illnesses. As of July 2024, investigations by Japan’s Ministry of Health, Labor and Welfare and national research institutions are ongoing. Preliminary findings suggest mold contamination during the cultivation process may have resulted in the production of compounds like pulchellin acid.

While the investigation continues, this incident has reignited discussions about enforcing GMP requirements for supplement manufacturers and underscored the critical role of hygiene control in production environments.

Air and water are omnipresent in food facilities, yet often overlooked. This article explores microbial contamination risks through air and water, emphasizing the importance of viewing them as essential "sub-ingredients" in food production.

"Utilities" refer to equipment and resources not directly involved in manufacturing, such as water, air, and lighting. Standards like ISO 22000 require utility management as part of good manufacturing practices. In HACCP-based facilities, utilities like air and water play a key role under prerequisite programs (PRPs) or general hygiene programs.

The Importance of Air Cleanliness – Microbial Contamination from Air

In food and pharmaceutical factories, controlling air cleanliness is crucial for preventing mold growth.

Contamination has occurred when dust or condensation inside air conditioning systems supported microbial growth that then reached food products. Proper maintenance and hygiene of HVAC systems is therefore essential.

Preventing environmental contamination can reduce the initial microbial load of food products, which may help extend shelf life, reduce food waste, and contribute to UN Sustainable Development Goals SDGs.

Codex Guidelines

The Codex “General Principles of Food Hygiene” highlights air quality and ventilation in Chapter 1: GHP (Good Hygiene Practices), Section 3:

- Proper ventilation (natural or mechanical) should:

- Minimize airborne contamination such as aerosols and condensation droplets.

- Help regulate ambient temperature.

- Control odors affecting food suitability.

- Maintain humidity to prevent microbial growth or toxin production, especially in dried foods.

The ventilation system should be designed and constructed to prevent air from flowing from contaminated areas to clean areas. Air intakes must be monitored to prevent contamination by insects, dust, smoke, or odors. Equipment should be structured for easy cleaning, filter replacement, and upkeep.

Some countries adopt the "product zone" concept, where all areas, including overhead structures—where food can be exposed are subject to strict hygiene control. Take a bird's-eye view of your facility to assess contamination risks from ceilings, pipes, or condensation above food processing lines or kitchens.

U.S. Standards: Air Cleanliness in Food Facilities

In the United States, food production environments are regulated under various federal standards, most notably by the Food and Drug Administration (FDA) and U.S. Department of Agriculture (USDA). While the U.S. does not have uniform numerical thresholds for airborne microbial counts across all food categories, air quality is recognized as a critical factor in contamination control.

1. FDA Guidance

The FDA’s “Current Good Manufacturing Practice” (cGMP) under 21 CFR Part 117 – Subpart B (for human food) emphasizes the importance of air quality and facility maintenance:

- §117.20 (b)(4): "Air or other means of conveying ingredients, finished food, or food-contact surfaces must be maintained in a manner to protect against contamination."

- §117.35 (a): Cleaning and sanitizing of equipment and utensils must prevent cross-contamination.

- Environmental monitoring, especially in Ready-to-Eat (RTE) food production, is emphasized under preventive controls for pathogens like Listeria monocytogenes.

→ FDA Food Safety Modernization Act (FSMA) Preventive Controls Guidance

2. USDA Standards (Meat & Poultry Facilities)

For USDA-regulated plants, 9 CFR 416.2(b) mandates:

- Ventilation must minimize odors, vapors, and condensation that could lead to insanitary conditions or adulteration of product.

→ USDA FSIS Sanitation Performance Standards

3. Industry Best Practices: Air Sampling and Mold Monitoring

Although not mandated, industry often uses air sampling via settle plates or impact samplers to monitor airborne mold and bacterial spores. Reference guidelines include:

- Institute of Environmental Sciences and Technology (IEST) RP-CC006.3 for cleanroom classification (applicable to high-care food environments)

- ISO 14644-1: Cleanroom Classification is often adopted voluntarily in high-risk food areas

- Mold limits vary by company policy, but thresholds such as <10 CFU/plate/hour for yeasts and molds in high-care zones are commonly applied.

→ IEST Cleanroom Standards → ISO 14644 Information

4. Practical Monitoring Strategies

Air cleanliness is influenced by many variables: personnel flow, gowning, material entry, pressure differentials, and cleaning schedules. While not regulated by specific numbers, routine environmental monitoring programs (EMPs) are a key part of HACCP-based food safety systems. Results from airborne microbial tests (e.g., settled plates or volumetric samplers) should be evaluated over time to detect trends and drive corrective actions.

For practical mold monitoring:

- Use surface and air settled plates such as DRBC agar or SDA (Sabouraud Dextrose Agar)

- Monitor compressed air systems if used in direct product contact (per GFSI/BRC/SQF requirements)

Key Points for Mold Prevention – Focus on Proactive Control

Poor air management increases the risk of mold contamination in products.

Different molds are associated with different food types. For instance:

- Bread: Aspergillus and Penicillium

- Rice cakes: Cladosporium and Aspergillus

Understanding the species that are likely to affect your product, and their biology is essential for targeted control. Prevention is the key—once mold grows, removal is difficult. Measures should aim to stop growth before it starts.

Common molds found in food facilities tend to be:

- Sensitive to heat and dryness

- Unable to grow without oxygen

- Inhibited by refrigeration and unable to grow when frozen

Therefore, keeping surfaces and equipment dry, cold storage, or using oxygen absorbers in packaging are effective controls.

Because mold can spread via dust or particles, air filtration is also beneficial. Ethanol, chlorine-based agents, ozone, and acidic electrolyzed water are effective disinfectants. UV light works on exposed surfaces but is ineffective in shadows or hidden areas.

Recommendation: Rapid Testing

Traditionally, mold counts in food or feed are measured using Potato Dextrose Agar (PDA) in Japan, while ISO 21527-1 recommends DRBC (Dichloran Rose Bengal Chloramphenicol) Agar. These methods are time-consuming and require media preparation and 5+ days of incubation.

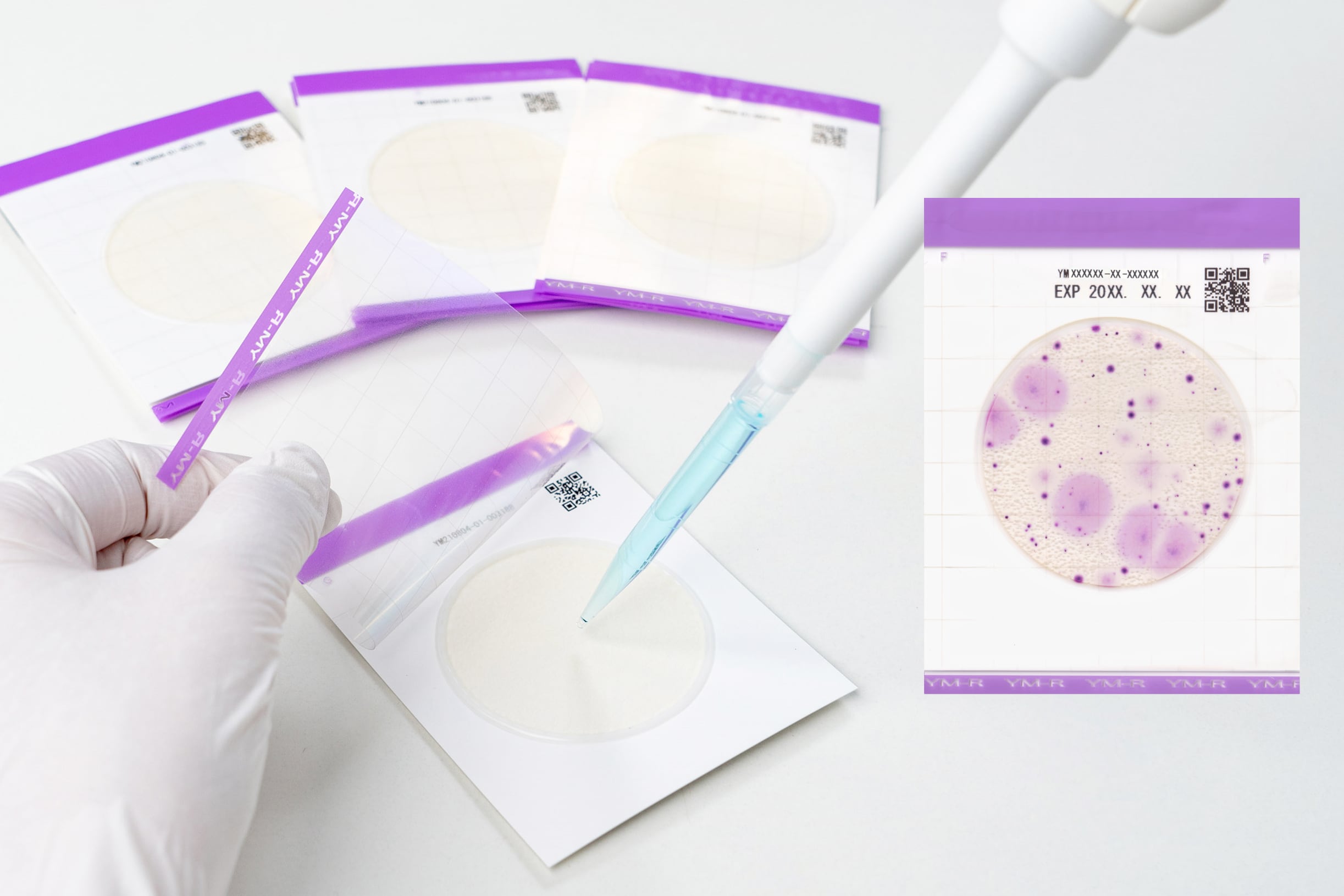

A practical alternative is using rapid, ready-to-use media, such as the Easy Plate™ series by Kikkoman Biochemifa, including:

- Easy Plate AC (for aerobic count)

- Easy Plate YM-R (for yeast and mold count)

These can be used to monitor air cleanliness. Additionally, the ATP Test (Kikkoman A3) (Lumitester & LuciPac A3) is useful for verifying utility cleanliness.

Figure 1: Easy Plate YM-R (left) and Lumitester & LuciPac A3 (right)

Water, Ice, and Steam Hygiene Management

1. Foodborne Illness from Water

In August 2023, approximately 900 people suffered food poisoning from Campylobacter after eating meals (such as flowing somen noodles) made with spring water. Japan’s Waterworks Act governs water quality, but untreated natural sources like spring water require special care.

Some may associate Campylobacter only with chicken, but it can also be waterborne. In 1982, a massive waterborne outbreak caused by Campylobacter and pathogenic E. coli affected over 7,700 people in Hokkaido. Investigations found the cause to be untreated water due to broken chlorination systems.

In 1997, another outbreak occurred at a summer festival when “cooling ice” used for storing food was mistakenly used for shaved ice, leading to secondary contamination.

2. Global Standards and Guidelines

Codex GHP Section 7.3 on water states:

- Water, ice, and steam must be appropriate for their intended use based on a risk-based approach and should not contaminate food.

- Storage and handling must prevent contamination.

- Steam used in direct contact with food must not carry contaminants.

- Non-potable water (e.g., for firefighting) must not mix with potable water systems.

Recycled or reclaimed water must be treated to ensure food safety is not compromised.

WHO’s "Five Keys to Safer Food" also includes the use of safe water and raw materials as a core principle, along with:

- Keep clean

- Separate raw and cooked

- Cook thoroughly

- Keep food at safe temperatures

- Use safe water and raw materials

Proper design and maintenance of tanks, pumps, pipes, and water heating systems are essential. Structures should allow easy cleaning, secure sealing, and locking features—for hygiene and food defense.

3. Recommendation: Rapid Testing

In addition to routine inspections, microbial water testing is important. For self-monitoring:

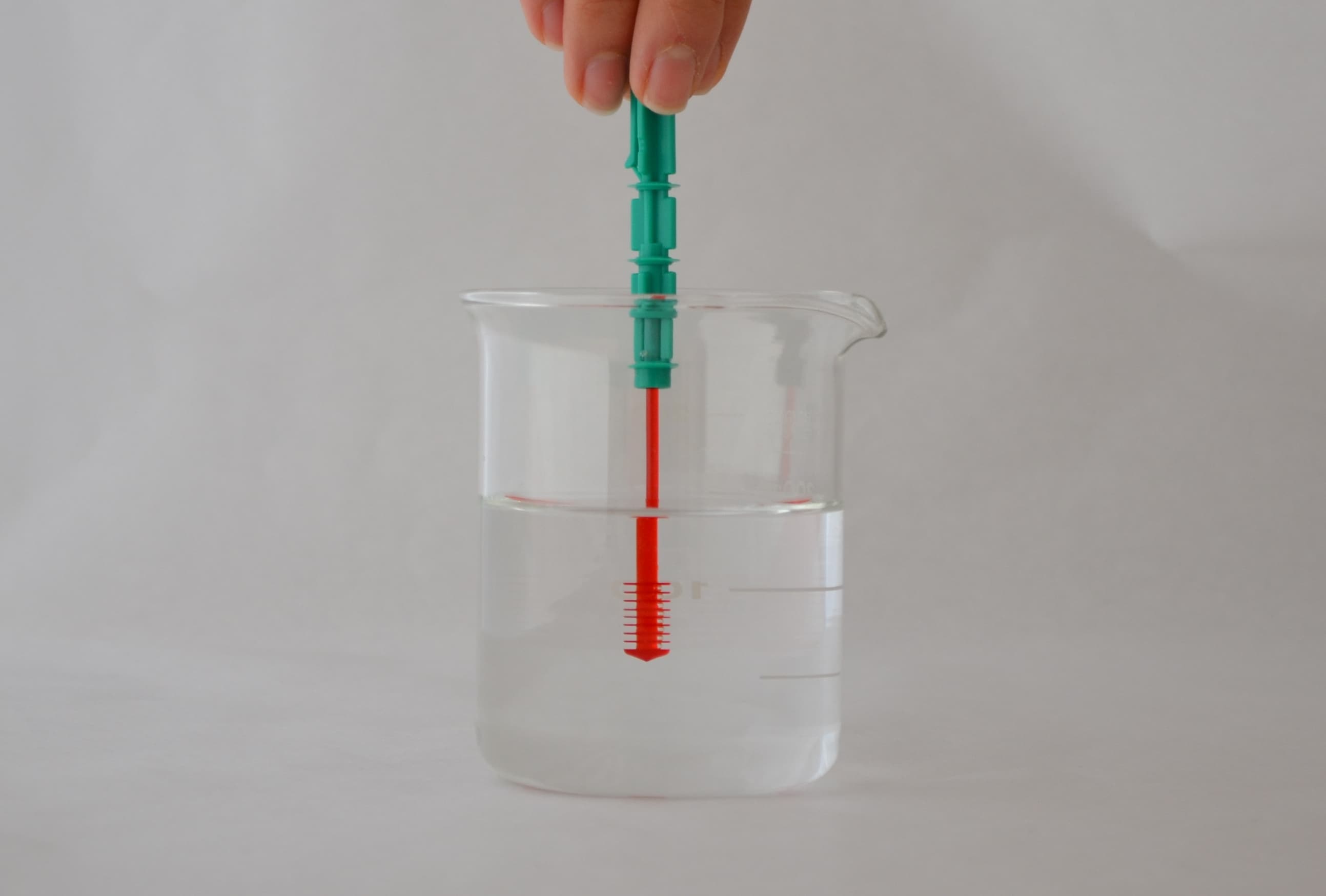

- LuciPac A3 Water (ATP test for liquids)

- LuciPac A3 Microbial Detection Kit for Liquids

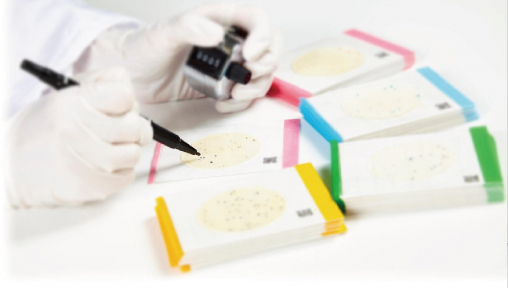

- Easy Plate (ready-to-use media)

These can verify hygiene conditions of water systems. The A3 ATP swab method is also effective for surface checks

Figure 2: From left—LuciPac A3 Surface, LuciPac A3 Water, LuciPac A3 Microbial Detection Kit

Figure 3: Easy Plate microbial test film

In food manufacturing, air and water must be recognized as indispensable sub-ingredients. Why not take a fresh look at your general hygiene practices with a focus on these essential utilities?